Dentistry, Technology & HVEvolution

The Idea HVE has to have 8mm bore opening is scientifically FLAWED!

Dentistry Technology & HVEvolution

Written by Laura Emmons RDH 2015

In recent years, the dental industry has experienced many changes. The evolution of dentistry has

caused a quiet revolution with those who tend to resist change. Post 2020 due to Covid 19 outbreak, New State health regulation mandates and CDC compliance have been adopted in many states and provinces in the USA and Canada. Clinicians who have worked in dentistry for years are being challenged to “bite the bullet” to leave old outdated methods of practice and use advanced technology devices. Many clinics are feeling pressure to evolve just to keep up and comply with the new standards of care.

There are now new HVE hybrid evacuation devices available to help dental professionals perform procedures with better health and safety along with improved ergonomics.

Many decades ago, In order to manage pooling water in the oral cavity during dental procedures, patients use to swish with water and spit in a round shaped bowl called a Cuspidor. As the years passed, air evacuation systems came along. The dentist used a long strait evacuator tube to suction out the water in the mouth during procedures. Later, dental hygienists expanded the dental profession who were specially trained to clean a patients teeth using hand scaling instrumentation. The process of cleaning teeth by hand was found to be very labor intensive. Magneto restrictive devices came out in the 1950s which helped speed up scaling procedures in removing deposits on teeth. These new scaling devices were used mainly for patients with heavy stain and calculus.

Back then, many hygiene operatories were not plumbed for HVE or highspeed handpieces. Hygienists were forced to work in a operatory which usually only had basicially a chair and light, cuspidor a slow speed prophy angle and a low-volume evacuator (LVE) for evacuation of their paitents mouth. Use of a saliva ejector was easy to bend and adapt to the patient’s mouth and usually was hung inside the cheek allowing evacuation to be “hands free” while the hygienist used a mouth mirror in one hand and a scaler in the other.

Often, the hygienist required help from a dental assistant to use High volume evacuation to suction the water during ultrasonic scaling procedures where a high volume of water spray was occuring. When no assistant was available or if the operatory was not plumbed for HVE, the hygienist had to resort to using a

saliva ejector to manage all the excess waterspray.

Technology advanced quickly with improvements. Advanced magnetorestrictive) devices came on the

market along with air polishers and lasers. These devices were found beneficial and time saving for providers to use. Some clinicians who used standard HVE by themselves had ergonomic issues which cause repetitve strain injuries in the hand, wrist,arm, neck and back thus the thought of using HVE became a barrier to its use. The main complaint was the hose felt too heavy and stiff to angle in

the mouth. Due to the ease-of-use and convenience, hygienists gravitated to just using saliva ejectors and hands free apparatus for water management.

Photo above; Dentsply Cavitron (1)

Due to the 2020 outbreak of Covid 19, new health concerns awakened the dental community to a higher awareness of aerosols and the need for better protecting providers as well as patients. While illnesses are commonly shared in the workplace, the risk of exposure increases significantly for hygienists using powered instrumentation such as ultrasonic and air polishing devices. Some studies have shown bacteria and viruses can rapidly spread through spatter and aerosols generated from dental procedures and while it can’t be proven that a viral infection can spread via contaminated aerosols resulting from powered instrumentation it’s certainly offers one possible explanation for office wide epidemic’s that commonly occur. (6)

Powered instrumentation is in widespread use in North America, yet safety standards and regulations

concerning the use has not sufficiently evolved. Currently 35 out of the 50 states in the USA claim to have

adopted CDC infection control guidelines for dental infection control standards. 15 of these states have

adopted the guidelines within the last two years starting what appears to be a new trend. In the CDC

guidelines under (PPE)personal protective equipment it clearly states: “Aerosols can remain airborne for long

extended periods of time and may be inhaled. Aerosols should not be confused with the large particles that makes up the bulk of the

spray from hand-pieces and ultrasonic scaler‘s. The spray might contain certain aerosols (ie. particles of respirable size <10um).

“Appropriate work practices including use of dental dams (172) and high velocity air evacuation should minimize dissemination

of droplets, spatter and aerosols.(1)

In the CDC guidelines section under the Blood-borne pathogen‘s and aerosols section it also states: “To

prevent contact with splashes and spatter dental healthcare personnel should position patients properly and make appropriate use

of barriers (eg.,Face shields surgical masks gowns,rubber dams and high-volume evacuators.” (2)

Some clinicians are unaware and or ignorant where aerosol management is concerned. Few agencies

enforce compliance. Infection control guidelines and regulations are currently under review in the few

remaining states. We anticipate these reviews will result in new updated rule changes to include

Manditory use of HVE.

While HVE is a top recommended solution for controlling aerosols and reducing risk of contamination

by the ADA (2) and CDC,(1) some clinicians still at their own risk, use saliva ejectors. Isolation devices are also a common choice even though many have been scientifically proven to offer no safety protection from contaminated aerosols.

So what exactly is high volume/velocity evacuation(HVE)?

Definitions of Terms:

HVE: High Volume Evacuator: Device which can remove a large volume of cubic feet air in a short

amount of time.

CFM: Air volume measured in Cubic feet of air per minute.

InHg: Static pressure meassurement in inches of mercury.

Velocity: A speed function of cubic feet per minute and inches of mercury in air flow.

Velocity equals the speed of which air travels through a device.

High Velocity Evacuation: A function of a given amount of cubic feet per minute(CFM) and a measured

amount of inches of mercury (inmg), usually with an increase in air speed near a port or opening.

Terminus end point: The very tip or end of the device being used a the user end.

LVE: Low volume evacuator is a device with low cubic feet per minute.

In the article “Aerosols and Splatter in Dentistry” by Stephen K. Harrel and John Molinari,(2) For a suction system To

be classified as an HVE, it must remove a large volume of air within a short period.” (7)

Air volume is measured in cubic feet per minute (CFM). While both HVE and LVE maintain the same

static vacuum pressure (InHg) using the same vacuum system, the difference in air volume and velocity perfomance is due to device design. Saliva ejectors cannot remove enough air volume to be classified as HVE due to the small diameter of the tubing and not effective against aerosols because it pulls a significantly lower volume of air. *An HVE can remove airborne contamination as long as it can pull a large volume of air and offer a wide air path footprint.

So why do we need to be using HVE?

As discussed earlier, research shows that aerosols and splatter produced during dental procedures do

contain saliva, blood, bacteria and pathogen’s. This risks the spread of illnesses such as common cold,

Flu, influenza, herpes,SARS, Hep C, Candida Aures,TB and Covid 19 virus which especially is a concern for dental providers who work on patients with undiagnosed or undetected cases. Many clinicians have been duped into believing it is OK to only use a saliva ejector to manage the aerosolized water spray. From an infection control standpoint, providers don’t realize what is invisibly going on when generating aerosols. HVE offers the best solution for controlling aerosolized particles before they leave the mouth and studies have shown HVE to reduce over 90% of aerosols. (7)

Dental clinics have air compressors and a separate vacuum system.

The compressor runs by an electric motor which has pistons that pressurize air for the air water syringe and air motors such as high and low speed handpieces.

The vacuum system unit has its own electric motor which drives an impeller in order to create a vacuum. If a vacuum pump does not have enough inches of mercury (inhg)( Velocity) regardless of CFM

capacity, it can lower evacuation performance. Also when there are more users on the suction system, it tends to lower CFM and InHg. Dental maintence/repair technicians normally set the pressure switch to 10 to 12 InHg level of performance. Some larger vacuum units were set around 18-20 Hg and designed to be used in larger offices with several operatories with multiple HVE suctions were in use at the same time. I worked in an office where the vacuum system was rated for only six users. Currently, the office has 12 operatories and up to 12 users at any given point. The system is completely inadequate in suction performance when there are several clinicians using their HV evacuators at the same time.

In the article “Aerosols and Splatter In Dentistry“ by Harrell and Molinary, it

states, “The usual HVE used in dentistry has a large opening (usually 8 mm or greater) and is attached to an evacuation system that will remove a large volume of air (up to 100 cubic ft per minute).”(7)

This article was written in 2004 twenty years ago. Back then, a straight HVE tip plugged into the valve/tubing was the only main apparatus used at the terminus end point. There were really no other options available for clinicans to use. So, when they mentioned “evacuation system pulling 100 cubic feet per minute” and that it had to be “8mm or greater,” with all due respect the reference has to be about the strength of the vacuum motor and size of tubing used in installation to the on/off valve! 100 cubic feet per minute? Are you serious? This is an extreme exaggeration as most units would only be capable of 1/10th of that level of performance.

A simple math equation for calculating airflow measurments and speed is shown in the box on the left.

To simplify the equation in laymans terms,

1 cubic foot of air is equal to about 7.5 gallons.

100 cubic feet of air is approximately 748 gallons. A visual example would be to take two of the largest lawn and leaf garbage bags which are 42 gallons each and fill them with air. and then extract all the air from both bags in 1 minute! Hmmm… That is a task I don’t believe even NASA could accomplish. I have questions and concerns for any company which would base a claim like this using inacurate information in an attempt to bring credibility in the promotion of a product. The statement that an HVE has to have 8mm bore or larger is scientifically flawed.

I checked a healthy new evacuation system in the dental office where I work and it performed at a range of 9-10 cubic ft per minute with a static reading of 12 InHg at the valve opening terminus end!

100 CFM per minute may be the evacuation motor’s capacity but when airflow travels through long plumbed lines and through the hose tubing reaching to the terminus end of a device, it can be quite a different story especially if the system is not new, has a long way to travel through the plumbing and hoses, and has clogged lines.

In order to determine what the mean level for adequate HVE requires more research.

For now, providers should be using systems and devices which maximize air flow performance.

So what would one do to accurately measure cubic feet per minute (CFM)?

Cubic feet per minute of airflow is a difficult task to measure and this type of testing requires very

specialized equipment. Dental office repair technicians usually only check for inches of mercury (inhg).

This is only half the equation. To be more acurate, they would need to go into each clinical operatory and

actually check cubic feet per minute (CFM) at each station. Measuring cubic feet per minute at each

station is a necessity in order to determine the health of the system.

**Combinations of both static (InHg) and cubic feet per minute (CFM) is necessary to have a

healthy vacuum system.

A elementary timed water test can reveal a range of suction volume performance in devices

at their terminus end point. Use a stop watch and 1 cup of water and

measure the speed of how long it takes to suck up that water using a

straight HVE tip, then use the same procedure with a saliva ejector to set

the high and low benchmarks. One can then test other suction devices in

order to measure their performance.

Another scientific way to test air path width at the terminus end point is to

spread 1/4 cup salt or talc on a table and drag and evacuation device

through it in order to view the width of the air pathway through the device.

Analysis with this test can reveal a device with design flaws.

Today, technology has produced hybrid HVE devices with multiple hole patterns at the terminus end point. They offer a wider air path foot print which can capture more aerosolized water and spatter.

(Left: Air path foot print of HVE mirror compared to saliva ejector and standard HVE tip)

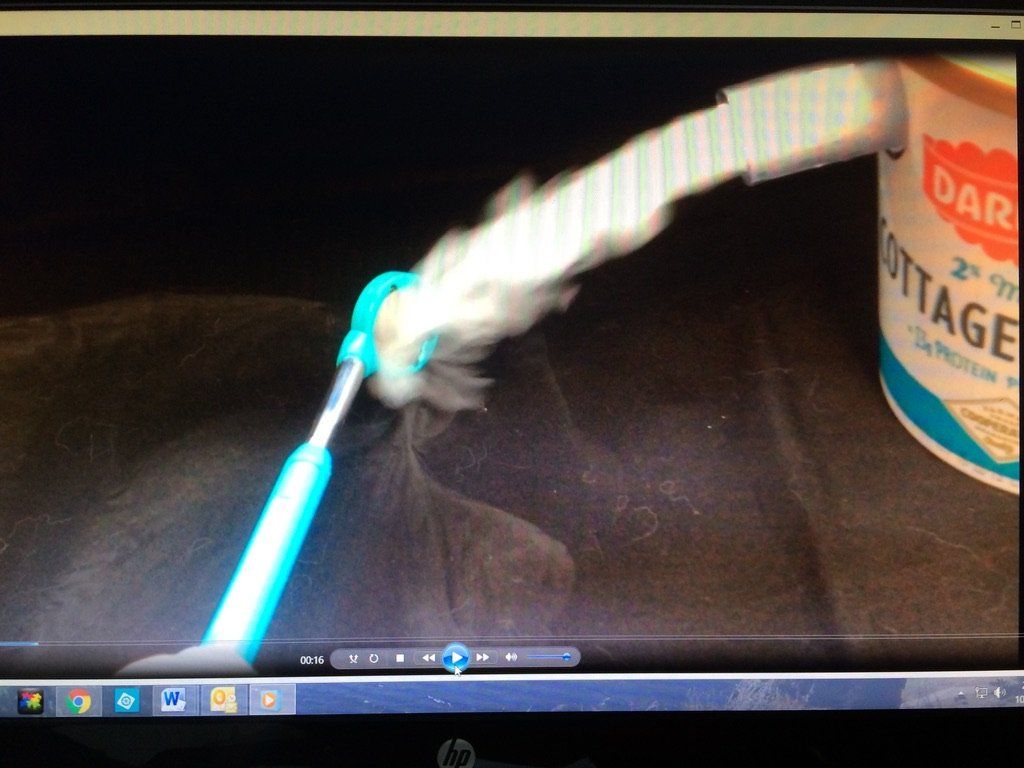

Photos of Air path ways demonstrated using Shark vacuum.

Note the vacuum hose wand air path width which parallels the large vacuum pathway.

The added brush head attachment contacts the floor with a broader surface area than just the hose end path enabling it to inhale

a wider air path of particles.

A television infomercial for the popular “Shark”vacuum cleaner compared it’s features against a competitor. Their demonstration was similar to what is needed for dental evacuation devices. Performance was tested to show how well the vacuum picked up particles on the carpet and floor and its wide air path which makes vacuuming a room faster. Mobility of the vacuum offered easy turning manuverability and access to difficult to reach places like under tables. The vacuum unit was more Ergonomic than other models when lifted up showing how light in weight it was to use.

Plain common sense would tell one to take a look at their home vacuum. The large diameter hose is a type of “ high volume”. If one were to just use the hose to clean, it would take a long time to suck up

all the dirt and dust particles. This is due to how the liner air pathway is channeled at

the terminus end point of the tube. Yet if one puts on a wider floor attachment, cleaning

can be completed much faster because of a wider “surface area foot print” or “air pathway” which can pull in a broader path of particulate! Aerosols are similar to small dust particles on the floor only they are alot less visible to the eye. Use of a uni-directional evacuator (like just using the straight vacuum hose ) only offers the diameters given width of an air pathway. Using a device with wider surface area /air path foot print at the terminus end point, can broaden the amount of particles picked up.

As demonstraited by the Shark vacuum example, design features allow cleaning tasks to be faster and easier. This is true for some newer dental evacuation devices as well.

Just having high inches of mercury (InHg) and high cubic feet per minute (CFM) does not mean great aerosol protection. A wider air path foot print at the terminus end point is also necessary.

**High volume, high port velocity and wide air pathway in dental evacuation is what is needed for proper management of water and aerosols.

Choosing the right device:

It is very surprising to find products on the market labeled as HVE but actually perform lower than the level of a saliva ejector. Remember when suctioning up water, it is approximately 1000 times more dense

than air. Most of the time in dentistry we are working with a mixture of mostly air with water and when

combined, produces spatter and aerosols.

Is there a solution? How do we address these problems and encourage more clinicians to use HVE as a safety standard? One way is dental clinicians need to be educated and learn more about a device’s design features in order to know what to look for. Device design is extremely important. A straight HVE tip has high volume and a given width of air pathway foot print. Another device may perform with slightly less air volume (CFM) but have higher port velocity and wider air path foot print enabling it to capture a broader pathway of aerosols.

Below: Examples of hand-held devices which offer high volume evacuation with wide hole pattern and wide air pathways. These can be purchased on the market. Many are ergonomic, lightweight and can be easily used in the mouth.

(1)Ergo Vac. (2)Purevac (3)multiaxis spiral suction (4) Angle Ease (5)Nu-bird integrated valve, “Banchi’

Below: Examples of hands-free stationary devices and adapters which utilize the HVE port. hands-free

evacuators were designed to collect water in the back of the mouth. Some designs have smaller tubing and hole size which cause limitations in the design, could restrict airflow and lower air volume (CFM) and air velocity. The balance of airflow is extremely important in order to keep the holes from getting plugged with tissue and become ineffective. These devices work for pooling water but according some studies,(4) not adequate for aerosol management.

(9) The Leaf. (10) LVE adapted to HVE (11) Blu Boa (12) Isolite

Evacuation is the Secondary Task to most dental procedures being performed, clinicians are more

likely to choose a device which offers the greatest convenience and comfort so they can focus on their

Primary Task.

Inverse Relationship:

Easy Secondary tasks increase efficiency of Primary tasks.

The more Complex the device design, Increased ease of use.

Difficulty with Secondary tasks reduce efficiency of Primary tasks.

The more Simple the device design, Decreased ease of use.

In the “Shark” vacuum cleaner demo, the three same factors which directly impact its use are Performance, Mobility and Ergonomics. These factors apply to dental use of HVE as well.

Performance: Clinicians need to know whether the power/static pressure (InHg), airflow volume

(CFM) and port velocity of their HVE performs to adequate safety levels. Clinicians need should rely on

data from independent and manufacture tests to determine the effectiveness of the devices they use, not just the word of a salesman representative. *Just because an evacuator plugs into an HVE suction port does not mean it is operating at an acceptable suction volume level on the terminus/end point. Vacuum performance can vary greatly from office to office. Clinicians need to look for devices which have high port velocity and wide air path foot print for good aerosol reduction.

Mobility: In order to work safer and efficiently, an HVE device needs to be light in weight and with the ability to be hand held approximately 6 mm to 15 mm away from the active aerosol generating tip. For example a stationary hands free device cannot be placed in the posterior of the mouth when the clinician works in the anterior area of the mouth. This is where more of the aerosols and splatter escape the evacuator eject into the air. Mobility is key and there are at least a dozen locations within the mouth

that clinicians need to access with HVE. Clinicians should look for designs that offer full range of mobility,

hand held and easy to manuver in all areas of the mouth. Broad air path evacuation with multiple ports

help enables the device to capture a wider area of particulate and water the problem is however that many of the designs have holes that just plug with tissue and render it ineffective. The long straight

tube of a standard HVE tip can be awkward to angle and handle. Clinicians have to pay careful attention to tip angulation to avoid getting the suction locked onto their patients cheek or tongue. A shorter length of this type of suction tip offers easier access and more acurate angulation to help stay close to the aerosol generating tip. Ultimately one needs to be able to move their suction device within the patient’s mouth without risking discomfort to patients while keeping focus on performing their primary task.

Ergonomics: This important factor can make the clinicians job more time consuming,

difficult to perform and cause injury. An average HVE hose weighs

approximately one pound and feels very stiff to manage. Hygienists complain of too much

pull and hose drag on the wrist and arm which can lead to repetitive strain injury. Because the usual

standard HVE units are hand held, clinicians are unable to use their mouth mirror for

indirect vision so they have to rely on direct vision only which can cause excess strain on

the neck and shoulders. New lighter weight designs have features that eliminate hose

twist and drag which can reduce the risk of repetitive strain injury. The HVE device needs

to have multi functional capability eliminating the need to switch devices mid procedure

(ie.. laying down the suction to pick up the mouth mirror to view.)

New hybrid device technology for HVE now come with more complex features that offer innovative solutions to the performance, mobiliity and ergonomic challenges of the standard straight HVE tip model.

One new HVE system on the market is the Purevac by Dentsply International. It performs with a wide air pathway. The opening offers aerosol reduction during ultrasonic scaling procedures. The hose is ergonomic with free rotation and is light weight making it easy to use.

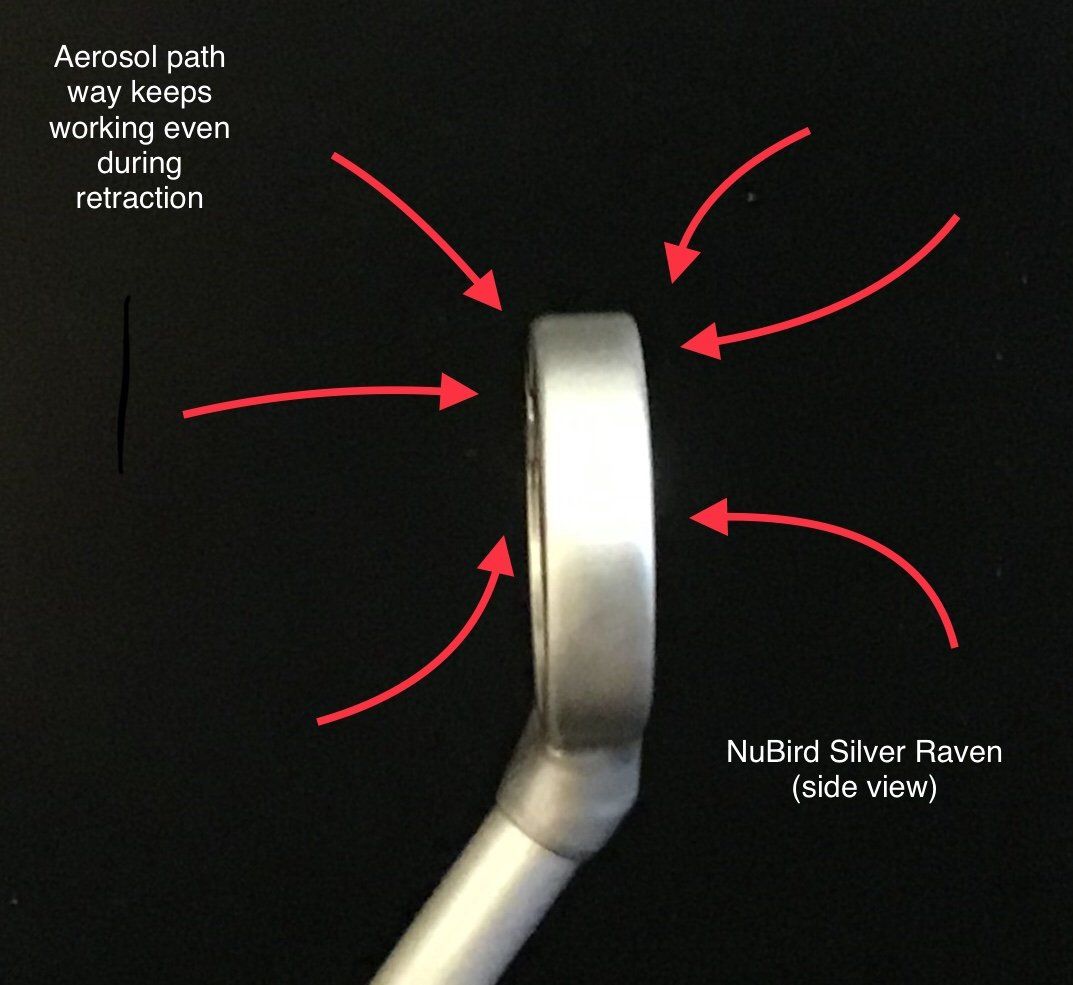

Another example of a new complex design hybrid is the Nu-Bird HVE Mirror System. The mirror head looks like a lollipop that has 10 multi-directional ports positioned around the periphery. These ports are very specific in size allowing the air pathway foot print to be approximately one inch in diameter. The patented design pulls air from both sides, front and back, versas a single-directional device like a standard HVE tip. As air flows through each of the ports, acceleration occurs while simultaneously pressure drops. That drop in pressure is the additional vacuum which helps quickly grab and capture aerosols and water in the mouth.

This is another example of “Bernoulli’s principle” at work and how high port velocity supplies a

“Venturi effect” that provides additional vacuum. The reason planes fly is the air rushing over the top of the wing creates a low pressure causing the wing to lift.

above Nu-bird mirror showing additional vacuum created due to Bernoulli’s principle” Photo on left of “Bernoulli’s principle’ and increased vacuum. (10)

There are several reasons dental clinicians would benefit from using the newer technology of an HVE/mirror system combo.

1) Higher accuracy with clear indirect vision.

2) Easier access and mobility in all areas of the mouth.

3) Ergonomic design features that reduce strain on hand and arm

4) Better water management and capture of generated aerosols

In the past, main stream dental clinicians have not had access to evacuation devices which

ergonomically utilized HVE but now can. Dental professionals should apply themselves to evolve in

learning to use some of these newer technology systems so they can benefit from the better

performance, health and safety and improved ergonomics and thus prolong their careers.

Laura Emmons, a graduate of Lake Washington Institute of Technology, works full time as a clinical hygienist. She and her husband own and operate a design and manufacturing company called Nu-Bird which

pioneered new technology of a mirror system which is combined with HVE for dental clinicians. You can reach Laura at info@nu-bird.com or visit nu-bird.com and face book. 5/24/2019

References:

1) Centers for Disease Control and Prevention. Guideline for infection Control in Dental Health-Care settings-2003

2) Aerosol and splatter Contamination from the Operative Site During Ultrasonic Scaling Sept 1998, volume 129, Issue 9 JADA,Pages 1241-1249

3). Aerosol and splatter. (J Am Dent Assoc. 1998) PMID: 9766105 (Pubmed-Indexed for MEDLINE) CDC guidelines: Bloodborne Pathogens anbd Aerosols

4) Holloman, J. L., Mauriello, S.M.,& Arnold,R.R. (2015) Comparison of suction device with saliva ejector for aerosol and spatter reduction during ultrasonic scaling. JADA,27-33

5) Avasth, A. 2018 “High Volume Evacuator (HVE) in reducing aerosol-an exploration worth by clinicians” Dental Health Oral disord The. 2018; 9 (3):165-166

6) Emmons, L.., Wu, C., Shutter,T., High-Volume evacuation: Aerosols- Its what you can’t see that can hurt you. RDH mag. July Issue 2017

7) Harrel,S.K.,&Mollinari,J.P.“Aerosols and Splatter in dentistry”JADA, Vol.135 April 2004,435

8) Kenyon TA, Valway SE,Ihle WW.Onorato IM, Castro KG. Transmission of multidrug-resistant Mycobacterium tuberculosis during a long airplane flight. N. Engl J Med 1996:334(15):933-8

9) Jacks, M. (2011) Protecting Yourself. Dimensions of Dental Hygiene. 9(8):26-29

10) youtu.be Creative Learning Bernoulli’s principle 3d animation Published on Oct 24, 2015

Conflict of Interest

The Author declares that there is no conflict of interest.

Photos 1,2,3,4,5,6,8,9,10,11,12 were from Google product websites.

5) Photo of Purevac Dentsply Professional from Dentsply International google website

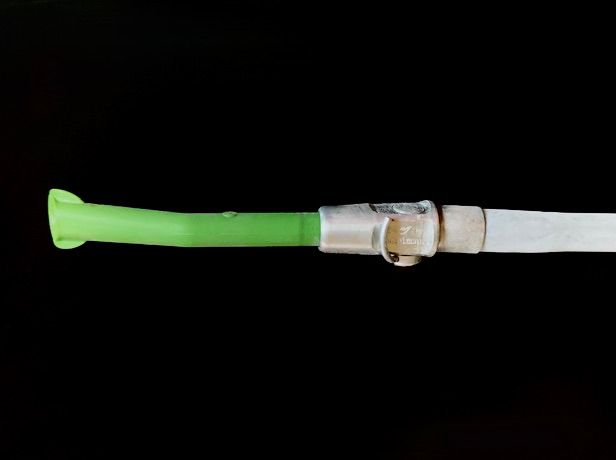

6) Nu-bird HVE systems HV valve and short HV tip.

6) Nu-bird HVE Adapter with short HVE tip Dentistry, The Evolution Revolution